Product Description

Heavy-Duty Robotic Positioner (7th Axis) — Motor & Drive Included — for KUKA KRC2 / KRC2 ed05

Designed & manufactured by PLC Merkezi Bulgaria — fully compatible external axis for industrial robots

- Scope: Complete 7th-axis positioner package with motor + drive, ready to integrate as an external axis.

- Controller compatibility: KUKA KRC2 / KRC2 ed05 as External Axis (E1…) with coordinated/asynchronous motion options. Fully suitable for use as a workpiece positioner/rotary table.

- Applications: welding & cutting (optimal angles), stone/marble processing, assembly & machining, large part handling, any task requiring extended reach & flexibility.

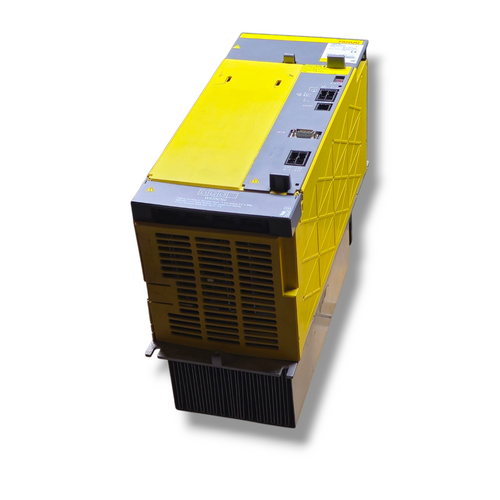

- Build: Heavy-duty frame, precision gear set, industrial servo motor & matching drive for smooth, accurate rotation under load.

Quick Facts

| Type Rotary workpiece positioner / 7th axis |

Integration External axis (E1…) on KRC2 / KRC2 ed05 |

| Motion Synchronous with robot path or asynchronous jogging |

Included Matched servo motor + drive, positioner body |

| Use Cases Welding, cutting, machining, stone/marble, assembly |

Condition Industrial build, shop-tested |

Compatibility & Integration

KUKA (KRC2 / KRC2 ed05): Configurable as External Axis (E1…) within KUKA System Software (KSS 5.x). Supports coordinated motion with the robot or independent asynchronous moves for positioning. Typical KRC2 ed05 cabinets use KUKA Servo Drive (KSD) modules with the controller’s power supply (e.g., KPS-27) for external axes.

- Setup via Axis Configuration (external axis count, mastering, limits, gear ratio).

- Use coordinated (path-synchronous) motion for welding/cutting around a part; switch to asynchronous for fast repositioning.

- Delivered with matched motor & drive to simplify commissioning.

ABB (general): Usable as a coordinated positioner with ABB controllers that support additional axes (e.g., IRC5 with Additional Axes/Positioner options), enabling synchronized robot-positioner paths for process accuracy.

Typical Applications

- Welding & cutting — rotate the workpiece for ideal torch angles and continuous seams.

- Stone & marble — rotary support for heavy slabs/blocks during processing.

- Assembly & machining — multi-side accessibility without re-clamping.

- Large part handling/positioning — expand robot reach and reduce cycle time.

Technical Notes

- Mechanical coupling, payload, and gear ratio must be set to match your tooling/fixture.

- Mastering/calibration is required after installation for precise coordinated motion.

- Electrical integration should be performed by qualified personnel in line with your controller’s external-axis documentation.

Delivery & Payment

Payment: Bank transfer (advance payment).

Dispatch: Ships the same day after payment is received.

Need photos, dimensions or wiring pinout before purchase? Contact us — we can provide additional details on request.

Keywords: KUKA 7th axis, external axis E1, rotary positioner, robot positioner, KRC2 ed05, KSS 5.x, KSD servo drive, KPS-27, welding positioner, turntable, ABB IRC5 positioner, coordinated motion, synchronous axis, asynchronous axis, workpiece positioner.